Our Materials

With the growing awareness of the need for sustainable change within the fashion industry, the aim of this project was to find ways to upcycle and re-use second-hand jeans in order to make highly functional and beautiful bags.

Jeans were focused on because according to the United Nations about 10,000 litres of water is used to make one pair of jeans. Any strategies that can use what is already created will help to lower the environmental impact of textile production. Also, jeans are readily available in second-hand stores and are frequently donated with the fabric still in a very useable condition. Jeans are worn, on average, one day per week for approximately four years before ending up landfill or burned.

The traceable denim label allows 100% traceability and linked to stock management when accepting and sorting original re-usable jeans with code. Reducing denim waste positively impact the sustainable fashion system with community workshops.

RECYCLED JEANS

The idea of a backpack came about as it is a useful everyday item and could be seen as a way to enable the consumer of the denim backpack to contribute to a sustainable fashion system.

Creating the backpack design was one of trial and error, with the final pattern pieces cut from the jeans fitting together like a jigsaw puzzle so that nothing was wasted.

RECYCLED JEANS

We use the 100% recycled denim for our bags. We aim to make the greatest quality bags from raw materials and perform just as virgin materials by doing our best with far less impact on the environment.

REUSABLE JEANS

From reusable jeans, we created tracking system to track the Ba-G sources on a label that allows new bag owners to log onto to donate and trace, view an image of the original jeans that were used to make the bags, with information about where they came from. Over time, the idea is to build an online community of people sharing stories about their bags who can see the positive effect they are having on the environment by buying an upcycled product.

REUSABLE JEANS

We also use reusable jeans to make

denim bags by collaborating with

companies and communities.

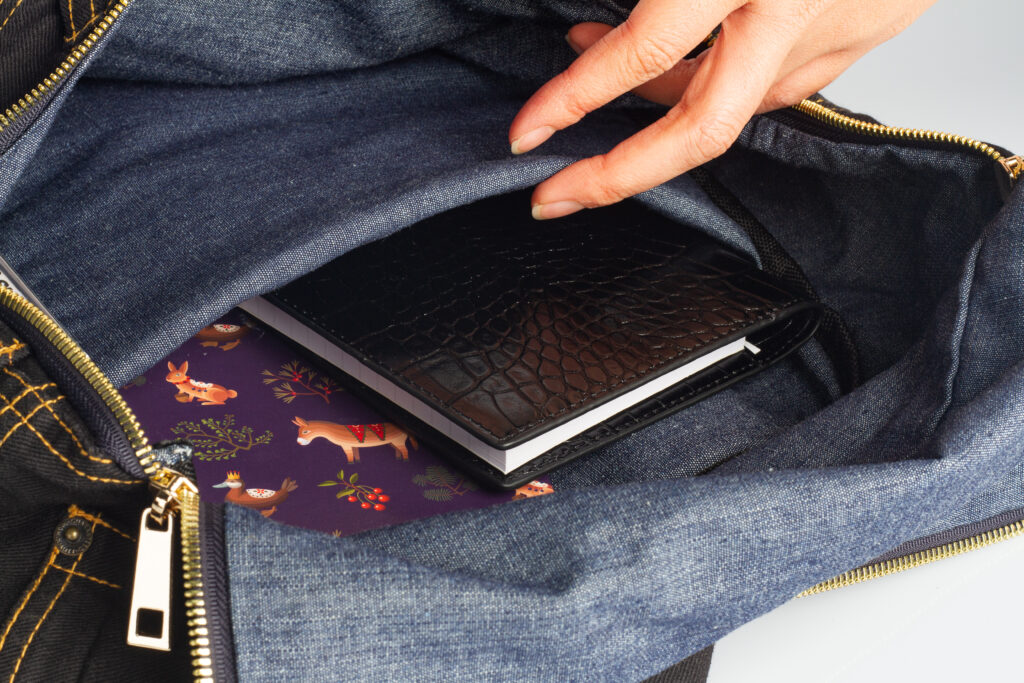

CHAMBRAY LINING

Many aspects of the final backpack design have been considered, including potential target markets and items that they would need to transport. Clever pockets are incorporated, using aspects from the original jeans in the design where possible. The bag lining gives the user the option to protect and keep their laptop safe.

CHAMBRAY LINING

We are using the off-cut leftover

reusable chambray fabrics for out lining.

The name of the brand is Cheong Ba-G. Cheong means clean blue denim in Korean. Cheong ba ji means jeans in Korean as we produce the patented design bag in South Korea and New Zealand.

In 2018, Fashion Designer Eunji were looking for a sustainable, functional, traceable upcycled denim bag to hold her daily purpose and work. Inspired by New Zealand beautiful nature to use as much as possible of one pair of second-hand jeans when designing the final bag (using pattern making and zero waste principles) and to create a digital tracking system that, along with labelling, helps consumers trace and better engage with the journey that one pair of jeans goes through when being upcycled started from New Zealand, South Korea, Australia.